In addition to providing evaluation data as per standard or specification, we can also make proposals regarding the methods, conditions, and equipment that best suit the evaluation aims, while also designing and manufacturing

any original equipment and jigs necessary in nonstandard evaluations.

We can provide comprehensive coverage of three different evaluation technologies, that include measurements, tests, and analysis, and are thus capable of fulfilling

multiple tasks involving different facilities, and proposing even more diverse evaluation methods.

We cope with various needs related to product precision measurement based on our wide range of accumulated knowledge and equipment capacity which only a commissioned company could offer.

We have one-stop solutions available with regard to reliability tests linked to research and development, and from jig manufacture and preparation through to specification/special tests.

Regardless of whether the evaluation sample is organic or inorganic, we can provide support in consistent evaluation ranging from analysis point identification through to sample preparation/observation/analysis.

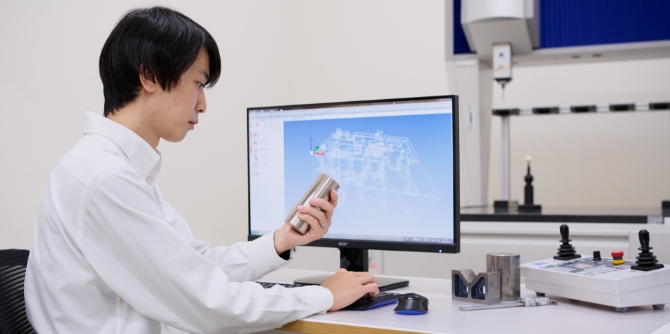

JTL is capable of optimal measurement for a variety of processes such as die-casting, resin molding, pressing, and cut parts. We respond to customer requirements in all areas, including precision measurement under temperature control and onsite measurement. We handle a broad range of needs ranging from individual measurements using manual procedures to multiple measurements using automatic programs, and installation of automatic measurement programs in customer's lineside measurement equipment.

We precisely measure part dimensions using the stationary precision measuring instrument in thermostatic chambers.

Three coordinate measuring machine, Image measuring machine, Measuring microscope, Profilometer, Roundness measuring machine, Contour shape measuring machine, Surface roughness measuring machine

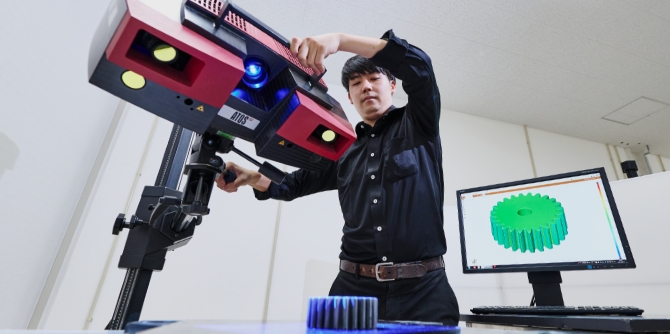

The advantages provided by the characteristics of non-contact methods enable shapes, parts, and materials to be measured, which is impossible via any contact method.

X-ray CT, Optical 3D digitizer

We create automatic measurement programs and install them in customer's lineside measurement equipment.

Various software of Tokyo Seimitsu, Mitutoyo, Leitz, and Hexagon

We perform onsite measurement for large parts, facilities, and other objects which cannot be transported.

Optical 3D digitizer, 3D laser scanner, Portable coordinate measuring machine

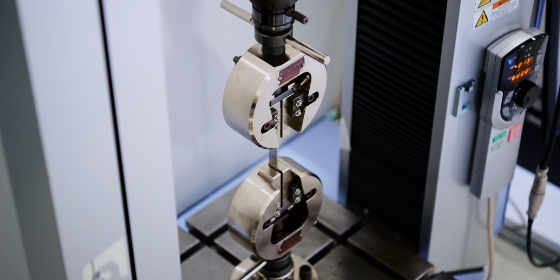

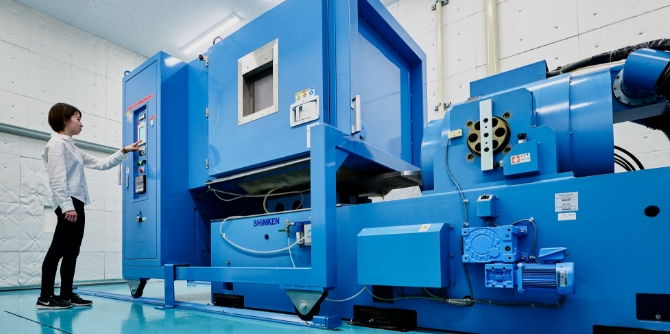

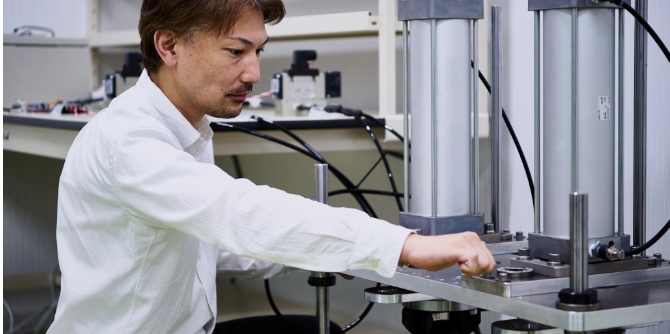

We support a wide range of tests which replicate the stress existing in the product usage environment. Not only can we evaluate the mechanical properties of materials, but we can also handle evaluation of product forming devices by using tension/compression testers, fatigue testers, electrical testers, etc. We have acquired ISO/IEC 17025 laboratory certification for our vibrating tests, thus ensuring reliable quality and technical capability meeting international standards.

We perform vibration durability tests meeting product characteristics and actual service conditions.

Vibration testing system,Impact and vibration testing system, CAE analysis

We can fulfill various environmental and electrical reliability tests as reliability tests, and then combined evaluations from the test results.

Thermal shock testing machine, Constant temperature and humidity testing machine, Salt spray testing machine, Combined cycle testing machine, Water resistance testing machine, Dust testing machine, Gas corrosion testing machine, Xenon weather meter, Discharge and charge testers, Electrical testers

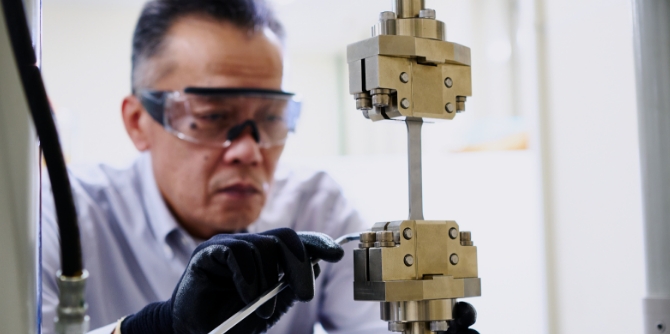

We handle all facets of test piece processing, jig manufacturing, and studying results of material's mechanical characteristics.

Tension and compression testing machine, Creep testing machine, Fatigue testing machine, Fatigue durability evaluation system, Frictional wear testing machine (ball-on disc method), Bond tester, Infrared thermography, Hardness tester

For requirements for nonstandard testing, we offer comprehensive solutions that include test method proposals, fabrication of equipment/jigs and performance of any such required tests.

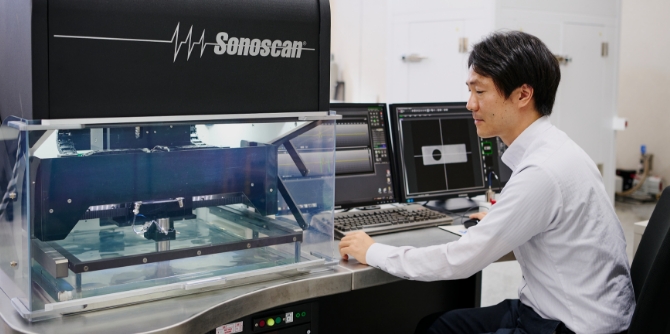

We provide integrated support ranging from advanced sample preparation using precision grinding, ion milling, and microtomes to observation/analysis using SEM, EPMA, etc. JTL can also perform non-destructive observations of internal structures by using acoustic microscopes and X-ray inspection devices.

Also, in the field of chemical analysis, we conduct various analyses for target components, elements and ions by using HPLC, GC, ICP, FT-IR, etc.

We investigate/offer information of product internal structure which can be obtained only by non-destructive analysis.

SAT, X-ray equipment, X-ray computed tomograph equipment, X-ray residual stress measuring machine

Our advanced and versatile sample adjustment technology realizes analysis of micro joining areas.

FIB, Ion milling equipment, Microtome, Laser opening device, Chemical liquid opening device, Polisher, Precision cutting machine

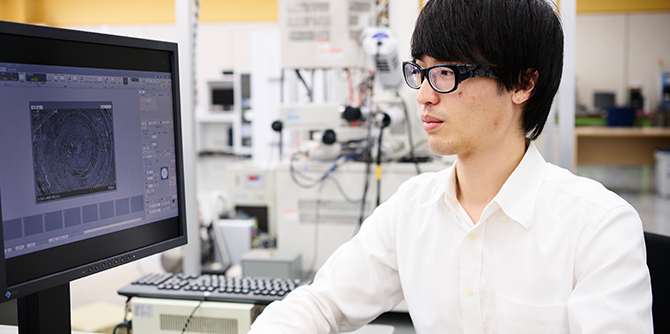

We offer information of sample conditions using various types of observation and analysis equipment.

FE-EPMA, XRF, RBS/ERDA, ESCA/XPS, SIMS, AFM, Nano indentation, FE-SEM, SEM, Digital microscope, Metallographic microscope, STEM, TEM, Raman, XRD

We handle elementary analysis for metals, outgassing analysis, measurement of drug concentrations in biological samples, etc.

IC, GC, HPLC, GC - MS, GC - MS / MS, LC - MS, LC - MS / MS, ICP - MS, ICP - AES, FT - IR, Microplate Readers

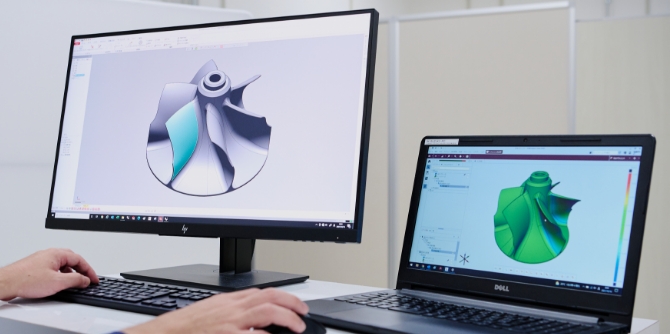

Mesh data acquired using 3D scanners and X-ray CT is used to create 3D CAD models.

Reverse software (Geomagic DesignX), 3DCAD (Rhinoceros, SolidWorks)

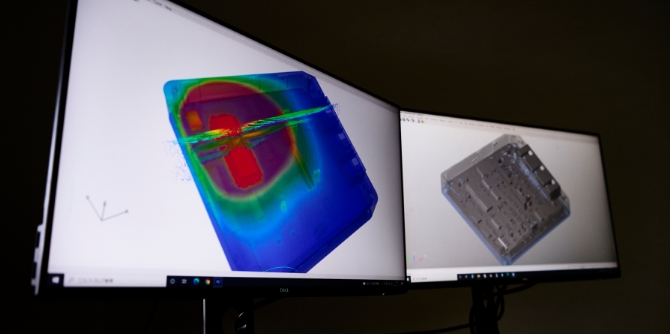

We can ensure comprehensive verification through structural analysis combined with actual testing; for example vibration and defect reproduction tests.

Analysis software (Hyper Works, Femap with NX Nastran, ANSYS, STREAM, SCRYU/Tetra, 3D-TIMON)

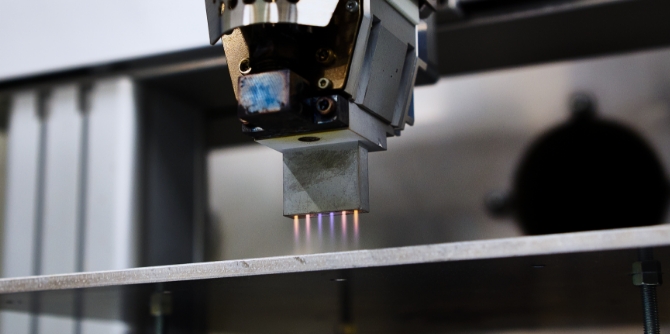

We can also undertake test specimen machining as well as the design and fabrication of jigs, which are essential in evaluation preparation.

5-axis machining center, NC milling machine, Boring machine, CNC lathe, Center lathe, Surface grinding machine, Radial drilling machine, Water jet, Wire electric discharge machine, Vertical saw machine, Micro cutter

Prototypes according to your required specifications can of course be manufactured.

Prototyping of bonded products, Prototyping of lithium-ion batteries, 3D printer

Do you have any problems with your evaluation activities?

JTL, as a reliable partner, will ensure that constant efforts are made to promptly and meticulously suit the situation of all our customers.

Please feel free to ask any questions, even if trivial, via the following email form.